It’s a hot, sunny August day in Nova Scotia’s Annapolis Valley and I’m crouched in a field, surrounded by mature flax plants. Farm work isn’t typically my forte, but I am a lover of linen. So when I saw the invitation from TapRoot Farms for volunteers to help bring in the flax harvest, I couldn’t resist. The long, thin stalks pull out easily by the handful, and we lay them in neat rows to await processing. Step by step, these plants will be transformed into golden tufts of flax fibre, ready to be spun into linen thread or yarn.

TapRoot is an anomaly. While Canadian farmers plant hundreds of thousands of hectares of flax every year, that’s to produce seed destined for your muffins, smoothies and linoleum flooring, not fibre for your linen closet. There is a history of growing flax for fibre in Canada. Many settlers from Europe did so to make their own textiles, and industrial production ramped up during the First and Second World Wars to supply the U.K.’s needs. But demand and production withered in the late 1940s in the face of the rise of synthetics such as polyester.

Now, however, awareness is increasing of the negative impact synthetic textiles are having on the planet – and our health. As the Canadian Energy Centre put it in a 2022 report, “it’s likely your clothes are comprised of petrochemical products.” But not only do synthetic textiles have a larger carbon footprint than natural ones, they’re among the culprits contributing toward the microplastic problem. Many people see linen – a biodegradable and durable plant fibre that requires minimal agricultural inputs and irrigation – as a solution that could also benefit local economies and make communities more self-reliant. The question is: What will it take to make Canadian linen viable again?

“I love wearing linen,” says Kathy Dunster, a professor in the School of Horticulture at Kwantlen Polytechnic University in B.C. “It’s a natural fibre and it’s so comfortable, and I got to thinking, where does it come from?” These musings set off a whole area of research for Dunster, who for years has been digging into the history of flax production in the province, as well as running field experiments to test how different varieties grow in the West Coast climate. People are “way more interested now in natural fibres,” she says. “And the world seems to be going that way: microplastics suck, and natural fibres are in.”

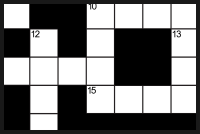

Flax is harvested at Common Roots Urban Farm in Halifax. The Canadian linen industry is minuscule, with the total land dedicated to fibre flax estimated to be fewer than 10 acres.

To grow linen, of course, you need seed. And those destined to become food aren’t right for the job, at least not for fine fabrics. So Dunster reached out several years ago to the Plant Gene Resources of Canada in Saskatoon, a sort of “living library” of plant material, and requested fibre-flax seed that would be appropriate to Lower Mainland growing conditions, especially in the face of climate change. “The technician sends me this note,” she recounts: “ ‘I’ve been very generous and given you 100 seeds of each variety.’ ” At six seeds per square inch, she adds, that’s not a lot of ground to cover. “And I think, we’re going to be at this for a long time.”

In Canada so far, the linen industry is minuscule. Counting test and artisan plots, the total land dedicated to fibre flax is currently probably fewer than 10 acres, says Alvin Ulrich of Biolin Research Inc. in Saskatoon – the equivalent of less than eight football fields. That said, he adds, it’s now being grown by perhaps five dozen people, up from fewer than five a few years ago. “No one is presently spinning or weaving linen on a commercial scale in North America,” he says, “although there are several ‘commercial artisan’ scale operations.” In comparison, the United Nations’ Food and Agriculture Organization estimates there were about 263,000 hectares (650,000 acres) of land growing fibre flax globally in 2022, the three biggest producers being France, Belarus and the Russian Federation.

Carol Hyland is a freelance graphic designer and part-time farmer. She and her husband own Alderley Grange, an almost four-acre piece of land not far from Victoria. Her parents both worked in Northern Ireland’s linen industry before the family emigrated, and when she was planning her crops, flax quickly came to mind. “I’m a textile junkie,” she says. “I did a deep dive and realized [flax] was really easy to grow.” She also discovered the nearby Field Five Farm, which grows grain to brew and distill and was already planting flax as a cover crop. “I thought, if that’s your fallow crop, then if you use my seed it’s a win-win,” she says.

Hyland returned from a trip south of the border with Linore, a variety of fibre flax developed in Oregon in the 1960s specifically for the Pacific Northwest climate. “[Field Five] planted it and we did our first acre,” she says. That was three years ago. Since then, she’s continued to plant to grow and sell seed, as well as inviting local weavers and spinners to pull flax for their own use.

Jennifer Green holds freshly harvested flax stalks at Common Roots Urban Farm in Halifax.

While she has dreams of spinning her crop herself, Hyland’s motivation right now is boosting awareness of the value of growing linen, which is why she also serves on the board of the North American Linen Association. “My incentive is to get people aware that [fibre flax] can be grown and is easy to grow,” she says. “We’re the largest exporter of flax in the world. It wouldn’t be a stretch for farmers to grow textile flax as well.” Though the eventual goal is to process it here too, she notes an intermediate step could be exporting raw materials. “They have a shortage in Europe” of flax for textiles, she says. “They need more places growing fibre.”

Ulrich says the global market for flax fibres – destined for textiles as well as insulation, building products, specialty paper and other uses – is about 600,000 to 800,000 tonnes annually, and there’s room for growth. “The price for linen fibres has never been higher,” he says, and there’s potential for Canadian farmers to enter the market. But quantity is a barrier. Spinners in China, India and elsewhere want to produce more linen and linen-blend fabrics, but they require volume guarantees that make it hard to enter the market. “The challenge is finding smaller users that are willing to blend small batches of Canadian flax fibres with traditionally sourced fibres from other countries,” Ulrich says. And while the finest fibre flax is expensive to grow relative to standard grain crops, “the profit potential is also higher.”

Another place with potential for growing fibre flax is Nova Scotia. In addition to (and in collaboration with) TapRoot Farms, Jennifer Green has been working with farmers via her Halifax-based Flaxmobile – a van and travelling flax consultancy – to revive the local linen industry one plot at a time.

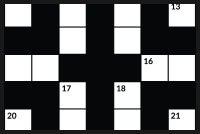

Green is a professor of textiles at NSCAD University and a spinner and weaver herself whose love for linen was kindled in her student days. One of her aims is to foster not just a flax-growing industry, but a linen-producing community. “There are so many social and cultural benefits to having agency around cloth and garment production,” she says. “Purchasing clothing from global corporations [means] that clothing is no longer a way to tell stories. It’s our identities being proposed by big business as opposed to being able to tell stories of our connection to place or to each other.”

Jennifer Green, professor of textiles at NSCAD University, aims to foster a linen-producing community in Canada.

Dunster, the B.C.-based horticulture professor, also believes there’s huge potential to develop a linen industry in Canada that could offer economic security as well as the security of lessening our dependence on the global market for textile production. “In my wildest dreams we would have hundreds of people growing and shipping to one central processing place, probably a co-operative,” she says. She envisions weaving in particular as a distributed task well suited to rural and First Nations communities facing population loss and a lack of economic opportunities. “The pieces are all there and the demand is there,” she says. “So how do we turn this into something that actually does all these good things for people?”

The answer is partially demand, says Hyland. “There have to be people saying, ‘I want natural fibres from North American farmers.’ ” Financial investment is also key, to kick-start a processing industry – not a huge one, at least at first, but enough that farmers have a market for their fibre-flax crops. “It’s really expensive to start an industry,” says Patricia Bishop, who co-owns TapRoot Farms. “People would love to be able to access Canadian-made linen fabric and I would love for it to exist, but I need a team of people to come and help.”

Bishop has been growing and processing flax for years and has run a number of pilots to get things off the ground: She launched a flax CSA (community-supported agriculture) project where participants received finished garments, and worked with a group of design students to create linen products to sell. A local weaver also makes tea towels using their linen, and she’s seen knitters create beautiful sweaters from TapRoot yarn.

Bishop is motivated in part by seeing products come to life: “It’s pretty amazing to see all these beautiful fibres transformed into clothes,” she says. Lisa Roberts, a former CSA member and current federal NDP candidate for Halifax, often wears TapRoot linen at events, for instance. “It’s always special to see her wearing her dress,” Bishop says. But it’s the deeper, more philosophical (yet eminently practical) concerns about the world that truly drive her. “We really believe it’s important to have this kind of rural infrastructure,” she says. “At some point in the future we’re going to need the capacity within our communities to feed and clothe ourselves, and I want it to be available.”